Your Cart is Empty

New seminar dates every first friday of the month! // Free international shipping available

New seminar dates every first friday of the month! // Free international shipping available

Kurse & Seminare

About Us

Coffee Sourcing - How we select the right coffees

September 24, 2020 2 min read

Did you know that we have at least one new Specialty Coffee in our range every month? Sometimes we even have two or three new ones for you. There is a long process behind it. Here we show you how it works for us.

As is always the case, we first have to be clear about what we want. What do we want the coffee to be like? Exciting, adventurous, comforting?

How should it have been grown, i.e. at what altitude, under what conditions, in which country? How should the coffee have been processed? How much coffee should be available from this harvest? Do the partners such as farmers and importers share our values in ecological, social and economic terms? When we have answered all these questions for ourselves, we contact our coffee importers and ask for samples.

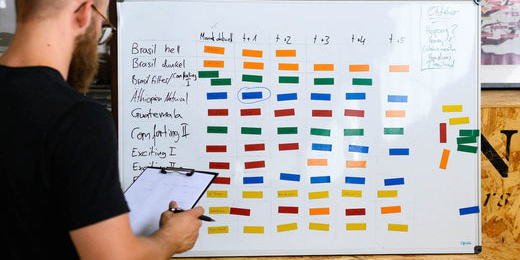

We then check the harvest date, available quantities and more info about the farm. We check the samples (visually) for defects. Then we do a sample roasting with the IKAWA Sample Roaster. The results are tested in a blind-cupping. We hide the name, origin and price in order to obtain a neutral and objective assessment of the coffee. The sensory evaluation is also important here: what does the coffee look like, how does it smell, how does it feel?

.

After blind-cupping, we decide which coffee we would like to include in our range for you. Once the decision has been made, we create further information for you, such as our information cards, which are enclosed with every order. An important step here is the aroma description. For this, we use the aroma wheel to give you a further clue for your purchase decision, in addition to the variety of coffee bean, the origin and the type of preparation.

So far we have gone through the process with just the samples. Now comes our actual order. The raw beans arrive. We compare the quality of the beans with the samples we tested before. Now it's time to develop the profiles of the individual coffees. This means that we determine with the roasting process in which direction the coffee should go. We have about 30 different roasting profiles stored in our IKAWA sample roaster. Once we have decided, it comes to the actual roasting process on our roaster from Giesen Coffee Roasters. Here we visually compare the beans with our samples. Monitoring is also done with the Cropster software. This allows us to follow the roasting process on the screen with the help of a graph. Another check takes place afterwards, the quality control. Here we check the appearance, smell and taste of the coffee and compare it again with our samples. Is this how we imagined the coffee? If everything fits, it is ready for packaging.

From our roastery in Frankfurt, it s then shipped directly to you at home or arrives at our cafés or many other cafés that serve our coffee. And then it's time to enjoy!

Join our Coffee Crew

10% discount on your first coffee order.And more: Sign up for our newsletter and never miss coffee releases, offers and background stories again.

Never miss out on great coffee again!

A new, freshly roasted coffee delivered to your home every month? Whether you prefer filter or espresso, our coffee subscription takes you on a regular sensory world tour through the world of coffee — with free worldwide shipping!